Combed Top vs. Roving: Same, But Different, Fibre Preparations

I’ll admit it: As a writer, I tend to affix too much importance to the choice and meaning of words. I overthink them. This has me wondering whether I’ve been a bit too rigid in my stance on the “combed top” vs. “roving” and “which-is-the-right-name?” debate.

Now, I’m ready to rethink my rigid ways.

Combed Top Vs. Roving: Are They The Same?

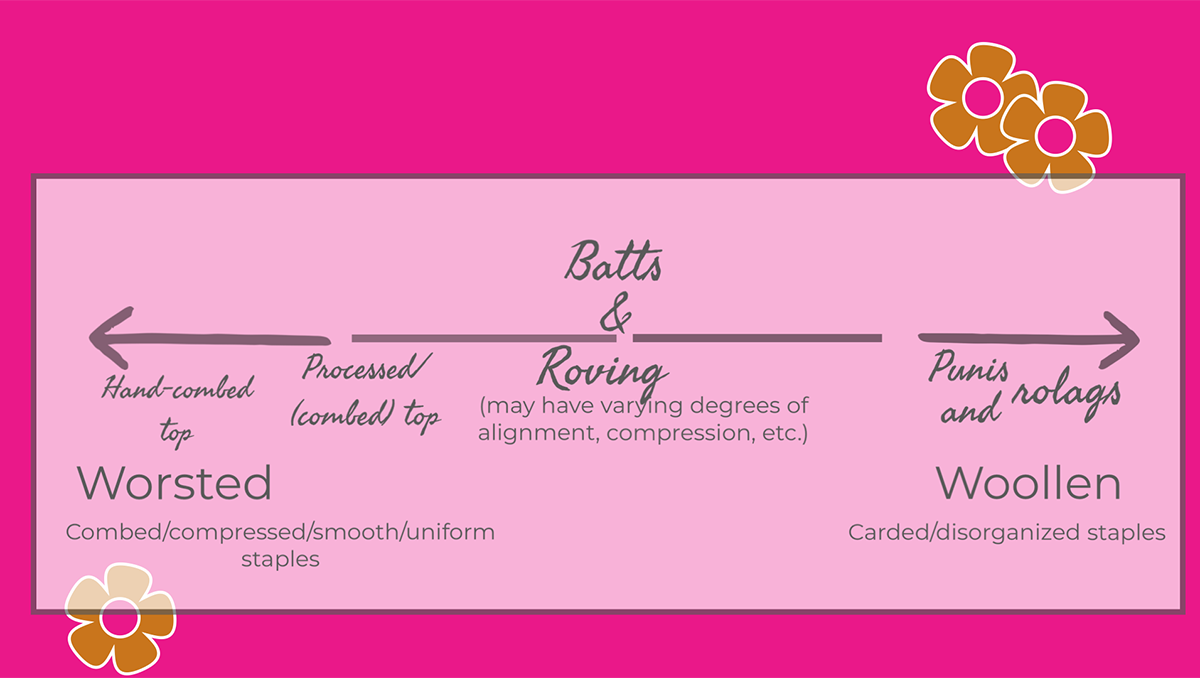

Well, no. Combed top is a close kin to roving, but the two types of fibre preparations are technically different. As is so often the case, applying the terms to the woollen vs. worsted continuum can help bring their meanings more clearly into focus. Top and roving are closely related, but they’re not quite the same preparations.

Defining Combed Top vs. Roving

Pre-Industrial Revolution

A true, 100% combed top is at the worsted end of the woollen to worsted spectrum. Combed top is a meticulous, hand-combed fibre preparation in which all small pieces (short bits of wool, second cuts, neps, etc.) have been combed out and the remaining fibres, now the same length, are drawn into parallel alignment. Even the roots and tips of these fibres are in an aligned format. This makes for the truest form of a fully worsted-spun yarn, where the fibres have been compressed and smoothed down during spinning and without allowing any air or twist energy into the drafting zone.

Roving, on the other hand, is always formed from a carded fibre preparation. This opened-up, fluffed fibre is then pulled (mostly) into alignment, either while still on the carder or, once it’s been removed, in any number of ways. It’s amenable to being spun with most any draw and has countless handspun possibilities.

Post-Industrial Revolution

The Industrial Revolution made it possible to commercially process vast amounts of fibre (and yarn) consistently. Efficient machinery took over the processing of fibre from human hands. Combed top—commonly referred to as “top” for short— was made with machines that combed out all the short bits of fibre and aligned and compressed what was left into what we know today.

The results are a highly consistent fibre preparation, with just a little bit of air within from the process, and minus its “perfectly worsted” tip-to-butt alignment. In a word, commercial top is fluffier than hand-combed top. It’s also almost always what hand-dyers and resellers use and list on their websites, often erroneously labelled as “roving.” Why? Honestly, I like to blame the internet age and search engine optimization (SEO), in which multiple keyword listings bring in more traffic than single-word listings. The words “top” and “roving” then became even more synonymous within the spinning community.

Like a roving, this top is a lot more flexible about its “best” draw than its hand-combed and hand-processed counterpart, and it may be spun many ways.

More confusing, processed combed top can be easily mistaken for roving at first glance… and even at a deeper one, especially if it’s been dyed—which tends to jumble and compress the fibres along the way. You’ve got to get up close and personal with both types of fibre to spot their differences.

How To Differentiate Between Commercial Combed Top And Roving

Tear off a few inches from each of your strips of fibre, then lay those down in front of you, where you’ve got plenty of light to help you assess them. Top will pull apart more cleanly at its edge than a roving.

Remember, top is combed and roving is carded. This means that the top preparation is smoothed and uniform, with its strands all the same length and running parallel to each other. If you pull apart the staple lengths (and you should), you’ll see this alignment. You’ll also notice their uniformity.

Carding will cause some level of jumbling of the strands—how much ultimately depends on its processing, whether by machine or by hand. The jumbling may be obvious, or it may be less so. When you tease apart a roving, you’re likely to spot a few telltale neps or second cuts, which are part of its imperfect beauty.

Holding the fibre up to the light may be helpful in distinguishing its makeup, as can examining a longer staple length top, such as Bluefaced Leicester or Corriedale.

Different mills may also use different equipment, too, so there’s not a specific standard for roving’s appearance. A few mills offer a particular preparation called pin-drafted roving, where an extra processing step pulls the strands more deeply into alignment. To me, a pin-drafted roving is practically indistinguishable from a processed combed top.

In The End, Do These Differences In Terminology Matter?

I think, for the sake of continued education, accuracy in terminology matters. But, using a less critical eye to re-examine the differences and similarities between combed top and roving has helped me to better understand just how close their relationship really is.

Whatever you call your spinning fibre… what matters is that you find joy in your spinning, as this is the best precursor to learning to process and spin your fibre exactly as you’d like it.

To learn more about in-depth fibre prep, take the School of SweetGeorgia’s Working from Fleece course, taught by Kim McKenna. Keep the conversation going on the School of SweetGeorgia forums or on the SweetGeorgia Discord channel.

Original publication: October 19th, 2023; Refreshed: April 15th, 2025

The post Combed Top vs. Roving: Same, But Different, Fibre Preparations appeared first on SweetGeorgia Yarns.

Comments

Post a Comment