The Drive System on Flyer/Bobbin Spinning Wheels

Do you struggle with your spinning? Is your wheel difficult to treadle? Does your wheel have poor take-up? Is your yarn consistently over-twisted? Before your yarn is taken up onto the bobbin, are you getting a lot of pig-tailing or curlicues in your yarn? If any of this sounds familiar, don’t let your first assumption be that you are doing something wrong or that you are not a very good spinner. Sometimes all it takes to get on the right track is to make sure your wheel is properly set up. But to do this you first need to understand how your wheel drive systems works.

Categories of Spinning Wheels

Spinning wheels can be divided into two main categories; spindle wheels and flyer/bobbin wheels. Well-known spindle wheels include the Great Wheel* and the Charka. There are two types of flyer/bobbin wheels; single-drive and double-drive wheels. Single-drive wheels are designed with either Scotch or Irish** tension.

The biggest differences between spindle wheels and flyer/bobbin wheels are:

- Spindle wheels operate at much higher ratios.

- On a spindle wheel, one hand works at turning the drive wheel while the other hand works at spinning the fibre. On flyer/bobbin wheels the action of treadling the wheel with one’s feet drives the drive wheel which leaves two hands available for spinning.

- Spinning on a spindle wheel is not a continuous fluid motion. After the twist is added to the yarn you pause, back the drive wheel off a bit, wind the make of yarn onto the spindle, and continue. On a flyer/bobbin wheel after the twist is added, you simply ease up on the tension and the make of yarn is pulled onto the bobbin.

The Parts of a Flyer/Bobbin Spinning Wheel

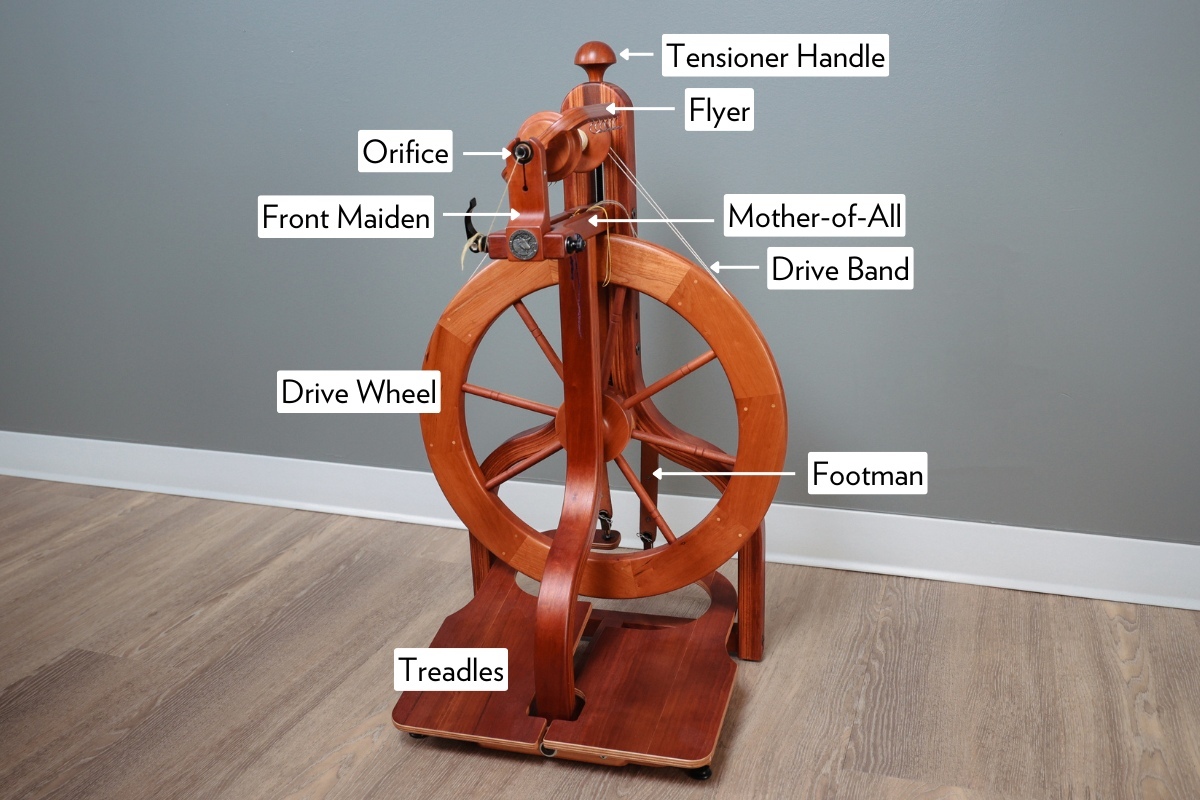

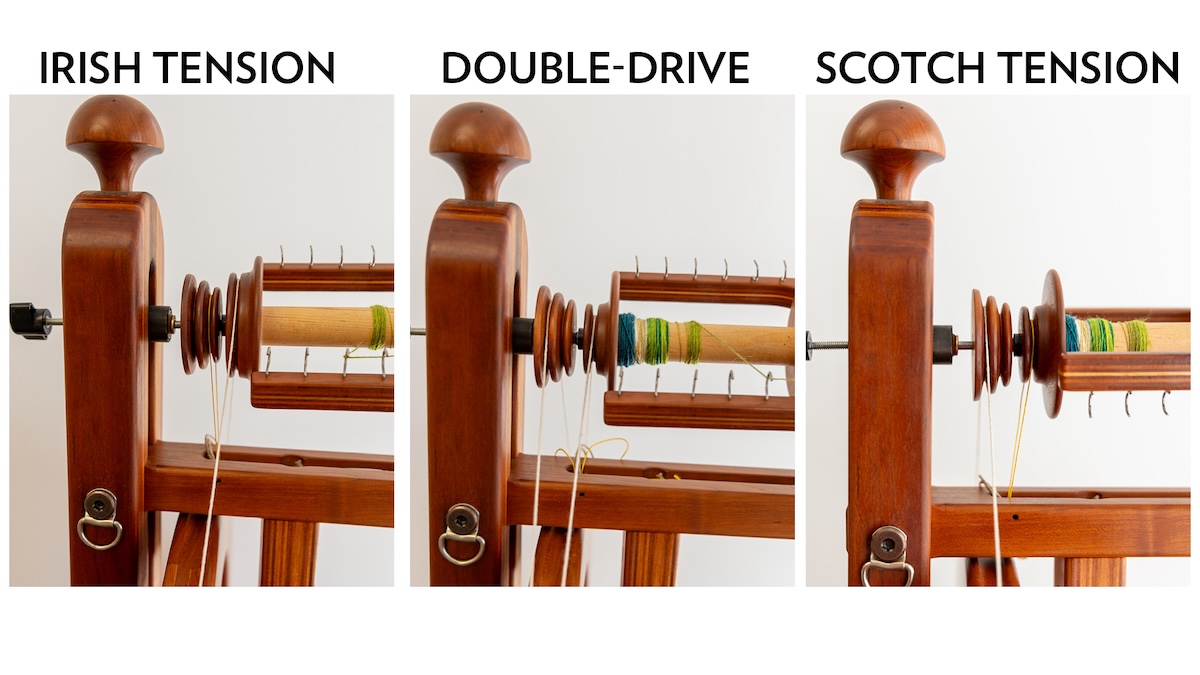

Before we review the different drive systems on flyer/bobbin wheels, let’s take a look at the parts of the spinning wheel and the function of each. When you press your foot down on the treadle it turns the drive wheel. As you continue to rock your foot back and forth on the treadle the footman moves up and down and turns the crankshaft. The crankshaft is connected to the drive wheel. A drive band connects the drive wheel to the flyer and/or bobbin. On a double-drive wheel, the drive band goes around both the bobbin and the flyer. On a Scotch tension wheel, the drive band sits on the flyer and on an Irish tension wheel it sits on the bobbin. Picture shown below.

A length of yarn called a leader, is attached to the bobbin’s core and threaded through the orifice. Fibre is joined to the leader. Your treadling action causes the flyer and/or bobbin to turn which creates twist in the fibre and makes yarn. On a double-drive wheel, there are two upright posts called maidens which support the flyer/bobbin mechanism. The base upon which the maidens sit is called the mother-of-all.

On a double-drive wheel, there is a tensioner handle. When turned one way it will move the mother-of-all closer to the drive wheel which reduces tension on the drive band. This in turn reduces take up onto the bobbin. When turned in the opposite direction, the mother-of-all moves farther from the drive wheel. This puts more tension on the drive band and increases take-up.

On Scotch and Irish tension wheels, take up onto the bobbin is increased or decreased by increasing or decreasing the tension on the brake band. The brake band on a Scotch tension wheel sits on a whorl on the flyer. On an Irish tension wheel, the brake band sits on the bobbin.

Scotch, Irish and Double-Drive Systems

Scotch Tension: The drive band on a Scotch tension wheel is fitted around the drive wheel and a whorl on the flyer. When you spin on a Scotch tension wheel, the flyer and bobbin work together to create twist so long as you are spinning and have tension on the yarn. When you feed the make*** of yarn onto the bobbin, the tension on the yarn is released, and the yarn moves forward and wraps around the bobbin. This is accomplished because the bobbin slows down, slips or stalls while the flyer continues to rotate around the bobbin. As the flyer continues to turn, the yarn is pulled onto the bobbin. This is why Scotch tension wheels are sometimes referred to as flyer-led wheels.

Irish Tension: The drive band on an Irish tension wheel fits around the drive wheel and a groove on the bobbin. Like the Scotch tension wheel, the flyer and bobbin work together to create twist so long as you are spinning and have tension on the yarn. With Irish tension, as the tension is released the yarn is fed onto the bobbin because the flyer slows down, slips, or stalls while the bobbin continues to turn and pull the yarn onto the bobbin. This is why Irish tension wheels are sometimes referred to as bobbin-led wheels.

Double-Drive: The double-drive wheel has a long drive band that is twisted into a figure of eight to create a loop on either side of a cross. One loop goes around the drive wheel and the bobbin, and the other loop is fitted around the drive wheel and the flyer. When you spin on a double-drive wheel, set up in double-drive, the flyer and bobbin work together to create twist as you spin. When you are ready to feed the yarn onto the bobbin, the flyer and bobbin continue to work together to pull the yarn onto the bobbin.

Take Up

Yarn is pulled onto the bobbin because the bobbin and flyers are designed to travel at different speeds. On the Scotch tension wheel, the brake band slows down the bobbin which allows the flyer to travel faster, and pull the yarn onto the bobbin. On the Irish tension wheel, the brake band on the flyer slows it down which causes the bobbin to travel faster and pull the yarn onto the bobbin. On a double-drive wheel, the flyer whorl is larger than the bobbin whorl which makes the flyer travel slower. It is important to adjust the take-up on a double-drive wheel as you spin. To adjust take up on Scotch and Irish tension wheels you stop spinning, make the adjustment, and then continue on.

So there you have the basic mechanics and differences between the three categories of flyer/bobbin wheels. The School of SweetGeorgia Tension Systems course also covers :

- How to make adjustments to your wheel to improve take up.

- How the cross is set up on your double-drive wheel when spinning Z versus S.

- How to adjust the tension for the different drive bands.

- Adjustments you can make to your wheel and spinning style to spin thicker and thinner yarns.

- How to increase the twists per inch if you have a lower ratios wheel.

- Some spinning wheel maintenance tips.

- How to improve the responsiveness of the Lendrum wheel to subtle increases and decreases in brake band tension.

Which Wheel is for You?

There are many different reasons we choose one wheel over another. Sometimes it is: for sentimental reasons, on the recommendation of a friend, because of the wheel’s provenance, we like the look of the wheel, it is within our price range, etc. You can also make your choice depending on the type of yarn you like to knit or weave with. If you like fine yarns, you may wish to consider a double-drive wheel. Its gentle take-up, smooth action, and higher ratios will help you spin fine lace-weight yarns. The smoother action of a double-drive wheel is also ideal for anyone who prefers to spin using a woollen draft. Irish tension wheels have a nice firm take-up and are great for working with longer stapled fibres and for spinning thicker or hard-wearing yarns. The range of staple lengths and fibres that can be spun on a Scotch tension wheel is largely dependent on how many ratios the wheel has. The more ratios the wider range of yarns and fibres you will be able to spin.

After you purchase a wheel, learn all you can about its mechanics/drive system. The first wheel I purchased was a Lendrum. I decided on the Lendrum because it was affordable, easy to treadle, and could be folded down during transport. When I purchased the Lendrum I knew absolutely nothing about drive systems and was quite happy with my handspun. Several years after I had learned to spin, my friend Judith Glibbery suggested that I should really learn more about the mechanics of my wheel. I took her sage advice and learned all I could about my wheel and, while I was at it, the drive systems on other wheels. This has served me well over the years. I now understand what adjustments I can make to my wheel to help it perform better. I am better at problem-solving when issues arise in my spinning. Plus, I am much better at deciding how to approach spinning new-to-me fibres. So take I encourage you to the time to learn as much as you about the mechanics of your wheel’s drive system. It will benefit you in the long run.

* The Great Wheel is also referred to as a Walking Wheel or a High Wheel.

** In some countries, Irish tension systems are called German tension systems.

*** A make of yarn is the length of newly/freshly spun singles.

Bibliography

- The Alden Amos Big Book of Handspinning, Alden Amos, 2001 (Interweave Press).

- Handspinning: Art & Technique, Allen Fannin, 1970 (Nostrand Reinhold).

- Spinning Wool: Beyond the Basics, Anne Field, 2010 (Trafalgar Square Books)

Are you interested in learning and developing your knowledge of spinning and spinning equipment further? We invite you to come and join us at the School of SweetGeorgia (SOS) for a range of fabulous online spinning courses for spinners of all levels. Available until the end of September, our annual Back to School sale is taking place with 15% off all SOS Memberships using the code BACKTOSCHOOL24! It’s the best time to join us and lock in this discounted rate for as long as you continue to be a member.

The post The Drive System on Flyer/Bobbin Spinning Wheels appeared first on SweetGeorgia Yarns.

Comments

Post a Comment